We have always developed our own packaging products. Today, we have a tremendously capable engineering department that includes product designers, engineers, and project managers, all of whom work closely with our senior management, sales team, location managers, and product managers.

We are always happy to make this concentrated expertise and our decades of experience in developing innovative plastic packaging available to our customers who need their own customized packaging solution.

But what does “successful packaging” actually mean? In our experience, it means packaging that not only stands out from the competition, but also provides significant, innovative benefits.

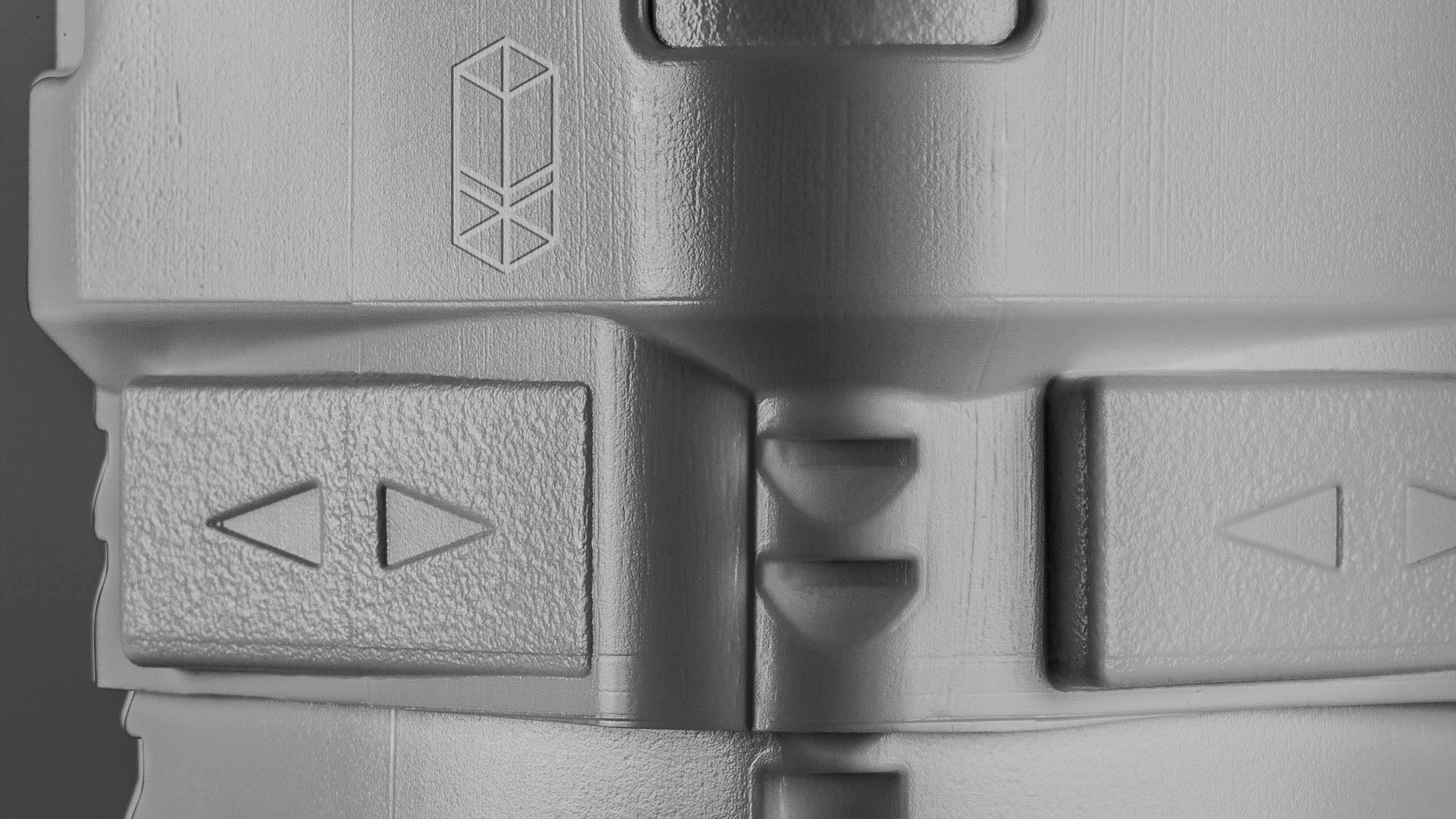

There are virtually limitless possibilities when it comes to giving your packaging its own, unique look. First of all, rose plastic offers you the choice of thousands of different types and sizes of packaging, most of which are available in a variety of materials. There is also a large choice of colors. Furthermore, a custom imprint or laser engraving can give your packaging a completely unique character and help to effectively differentiate your product from the competition.

So what happens if none of our 4,000 packaging solutions are quite right for your product – but giving up is simply not an option?

What are your options if your company or product just doesn’t quite match our “off-the-peg” packaging solutions? What if your product is highly specialized, or you have a very specific packaging design in mind?

No problem! We’ll collaborate with you to develop a customized packaging solution for your product. Regardless of whether you already have very specific ideas or are still somewhat “in the dark”, our expert team will help you every step of the way.

Take our specifications checklist, for example, which systematically uses our experience to query and record all relevant parameters, key data, and requirements that might otherwise get lost along the way. This allows you to focus on your own workload, while also creating a strong sense of security and commitment within the development process.After a thorough briefing and an internal feasibility check, we’ll prepare a rough cost estimate and a project plan for you. This will help you to keep an eye on your packaging budget as well as all the key dates and deadlines – and thus maintain a firm grip on the project.