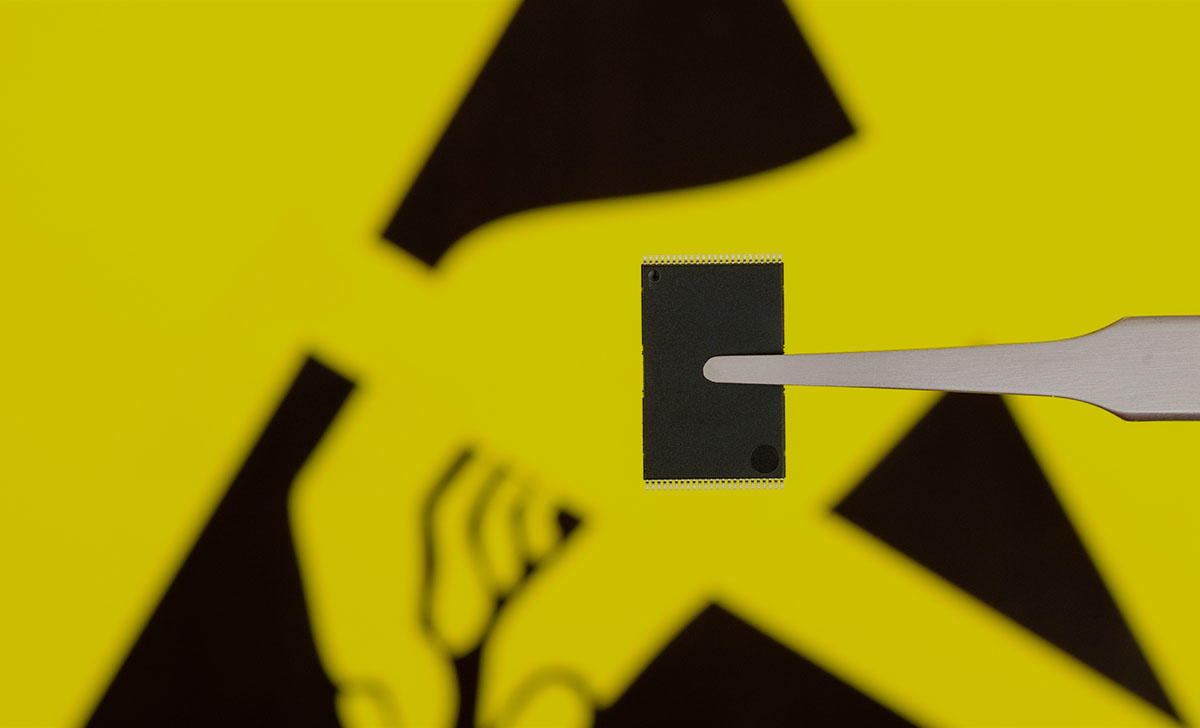

Electrostatic discharges (ESD) can cause serious damage to electronic components. Even low voltages are enough to partially or completely destroy electronic components. Our special ESD protective packaging has been specially developed to keep your electronic components safe from electrostatic discharges.

The principle is very simple: Our ESD protective packaging is made using special plastic additives, which make it electrically conductive. This conductivity prevents the build-up of electrostatic charges, and thus rapid discharge processes, thereby keeping your precious electronic components safe from harm. So you might say that, when we put our minds to it, the sparks really don’t fly.

ESD packaging: effective all-around protection for electronic components

During production of our ESD protective packaging, special additives are added to the plastic granules which reduce the surface resistance of the packaging and thus increase its conductivity. This prevents the build-up of electrostatic charges and thus rapid discharges from passing through the sensitive packaged goods. The goal here is to avoid fast, pulse-like discharges because these are far more damaging to electronic components than currents that flow off them continuously and slowly.

We produce our conductive packaging using either injection molding or blow molding processes. In terms of plastics, we use polypropylene (PP) or polyethylene (PE). During production, special additives are added to the plastic granules to increase the material’s conductivity. Our electrostatically dissipative materials have a surface resistance of 1012Ω, while our electrostatically conductive materials have a surface resistance of 104-6 Ω.

At rose plastic, we pride ourselves on providing a comprehensive service. That’s why we also supply tailor-made antistatic and conductive protective foam pads for all of our ESD protective packaging solutions.